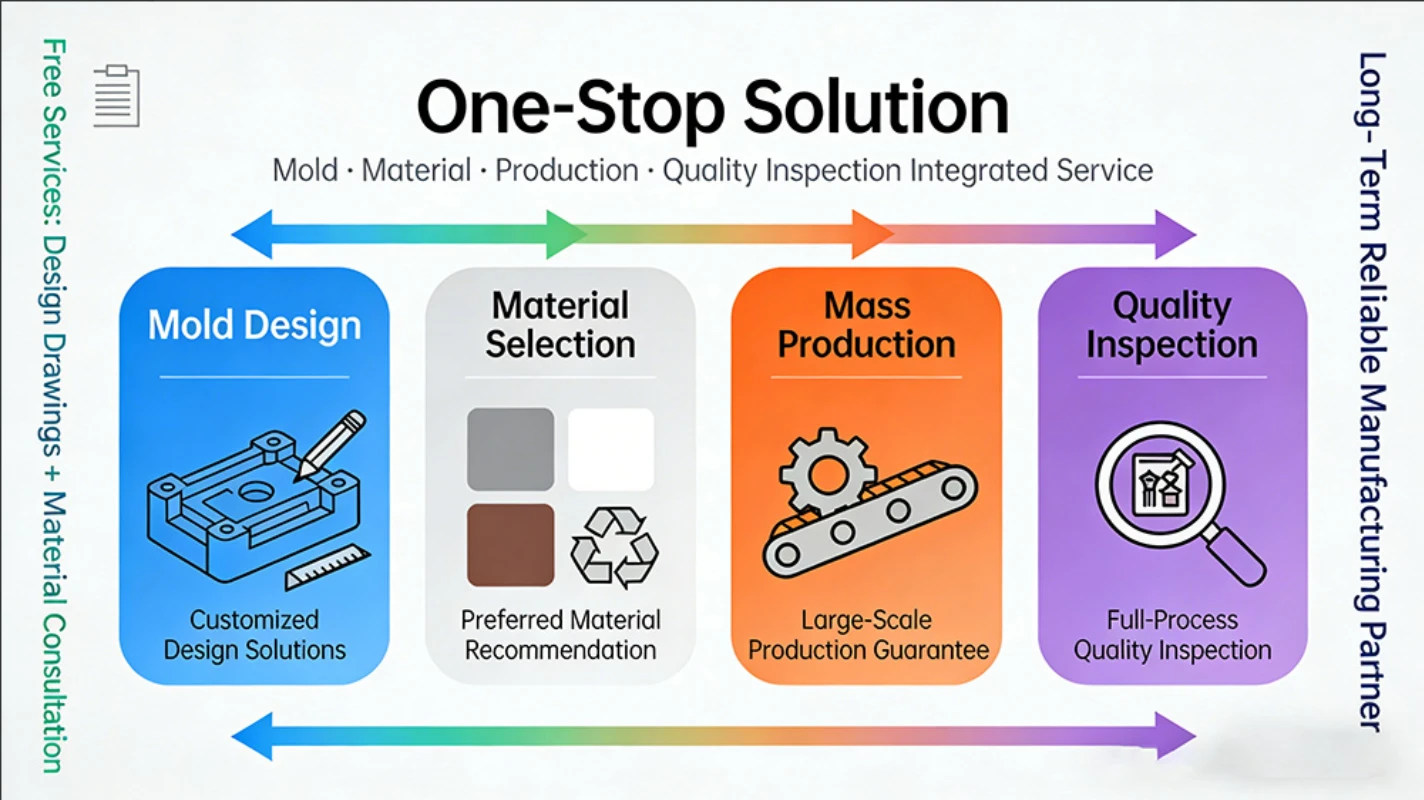

One-stop solution

From concept to mass production,

your comprehensive injection molding rubber partner

We offer a full range of services from product design, mold development, material selection, precision injection molding to post-processing and testing, ensuring seamless integration of every step of the project.

- Over 10 years of experience

- Over 2000 square meters of factory space

- Serving Europe, America, Japan, Southeast Asia and 100+ clients

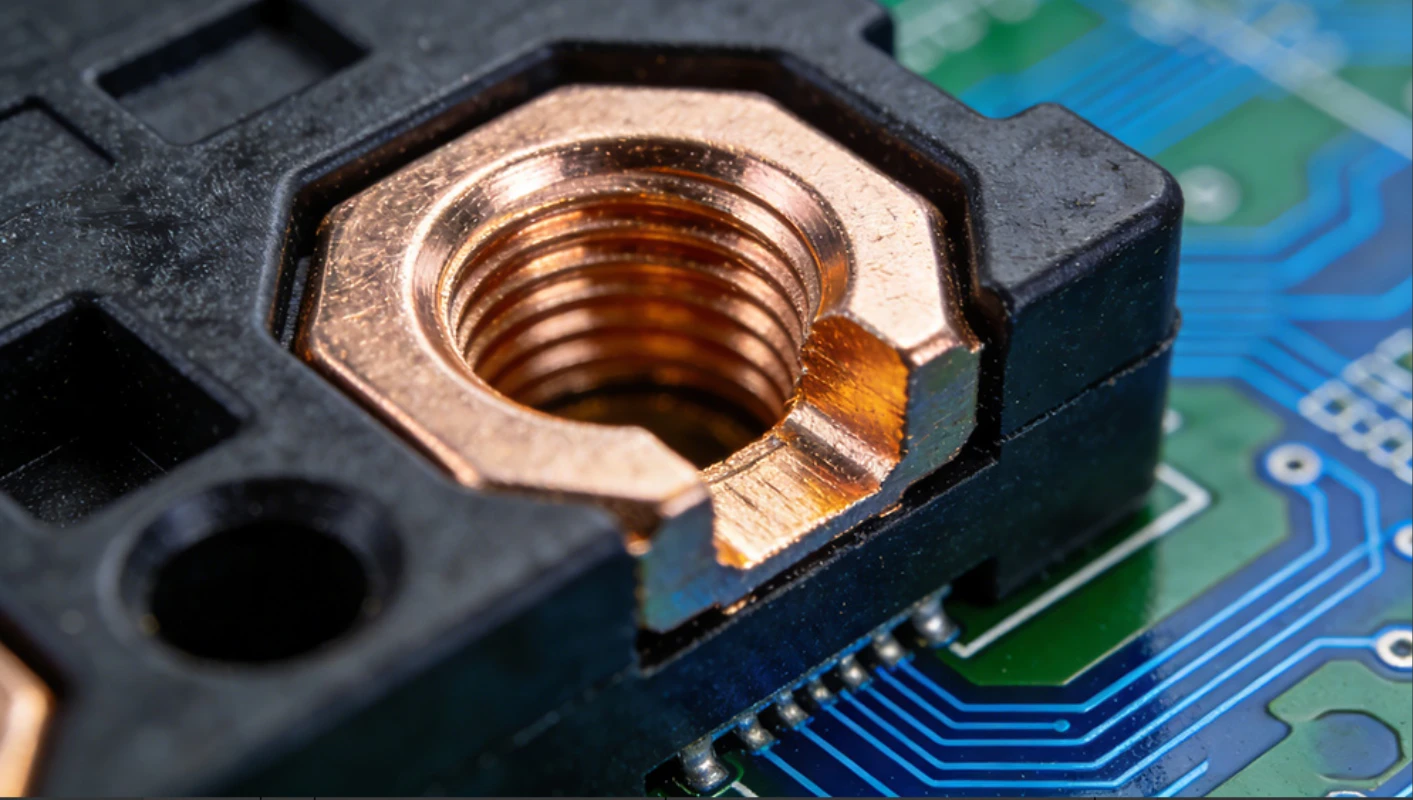

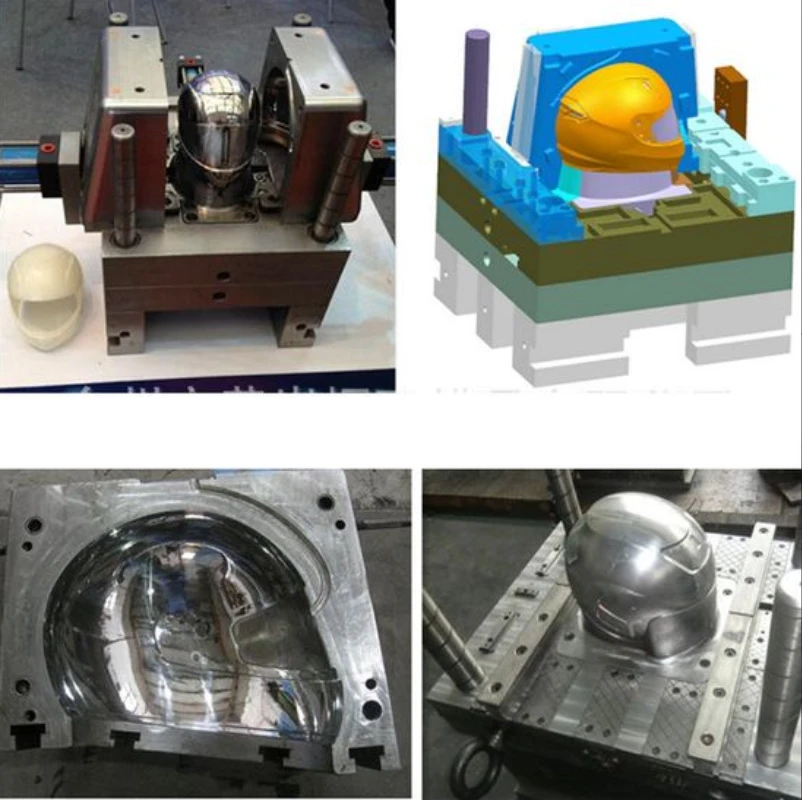

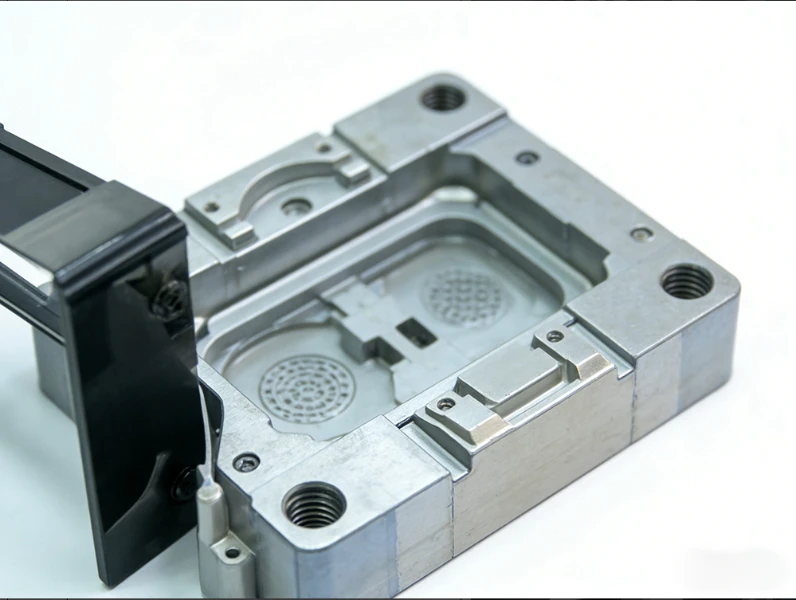

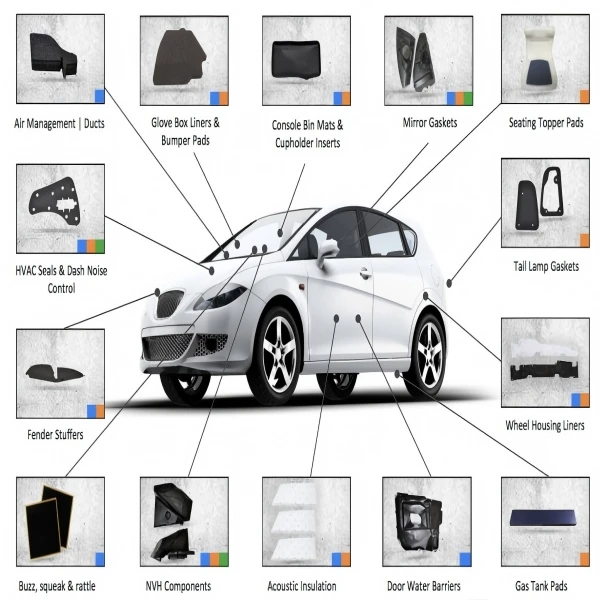

Customized production focusing on high-precision and stringent requirements

We specialize in complex processes such as liquid silicone (LSR) injection molding, micro-precision parts, and multi-material composites, meeting the highest standards of the automotive, electronics, consumer goods, and pet supplies industries.

With strict quality control,

we deliver every reliable product.

We have passed ISO 9001 quality management system certification and have complete testing equipment to ensure zero defects in the entire quality control process from raw materials to finished products.

Rapid prototyping and agile response accelerate your time to market.

We offer efficient sample development services and a professional technical support team to ensure your needs are met promptly and your projects are expedited.

![precision injection molding, global delivery – [chenfeng], a trustworthy emerging force resized](https://cfmold.com/wp-content/uploads/2025/12/precision-injection-molding-global-delivery-–-chenfeng-a-trustworthy-emerging-force_resized-768x512.webp)