Solution

From design to mass production:A one-stop solution for plastic molding

A Complete Guide for Global Manufacturers

Injection molding is one of the most widely used and reliable high-precision manufacturing processes for plastic and rubber parts. From consumer goods to automotive components and industrial equipment, injection molding enables manufacturers worldwide to bring durable, stable, and cost-effective products to market at scale.

Whether you are a brand owner, importer, distributor, or OEM partner, understanding how injection molding works will help you choose the right suppliers and achieve better production results.

Today, injection molding is the foundation of almost all modern industries and a pillar of mass production.It combines the advantages of high speed, high precision, and low cost, making it one of the most competitive production technologies in the global supply chain.

Common Injection Molding Industries:

Plastic storage boxes/turnover boxes, household storage boxes, organizers, trash cans, sorting bins, pet caddies, food bowls, housing components

Home appliance housings and panels, electronic device housings, industrial control equipment plastic housings, equipment internal structural supports

Industrial structural supports, equipment protective covers, functional connectors, engineering plastic frames.

Automotive interior and exterior trim parts, interior panels, support components, functional structural components, protective covers

Logistics turnover boxes, industrial pallets, plastic frames and containers

Building structural components, protective covers, mounting brackets

Mobile phone/tablet housings, mid-frames, buttons, brackets

The entire process includes several carefully controlled steps

A professional engineering team can design product drawings and create 3D models for you free of charge, and assess their manufacturability (DFM).

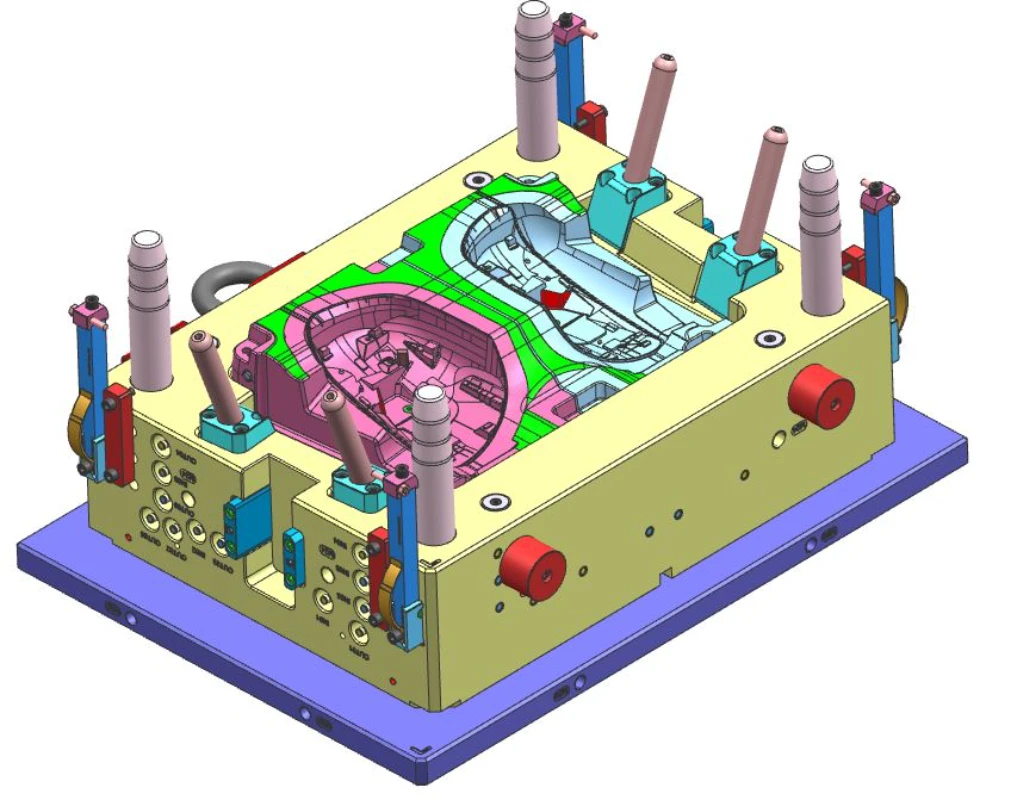

Engineers design the mold structure, cooling system, runner, and gating system to ensure stable production.

Steel molds are manufactured using CNC machining, EDM, polishing, and assembly processes.

Each product undergoes inspection for dimensions, appearance, strength, and functional performance.

Common materials include:

Home and Commercial Storage and Organization

PP injection molded storage boxes (also known as industrial turnover boxes or plastic storage boxes) are among the most mature, highest-volume, and internationally recognized large-scale polypropylene products in the injection molding industry.

These products are widely used in household storage, warehousing and logistics, supermarket distribution, industrial parts turnover, and cross-border e-commerce packaging. They are standard injection molded products with long-term stable demand in the international market.

Core Advantages of PP Injection Molded Storage Boxes:

Made from non-toxic, odorless, and recyclable PP (polypropylene) material, suitable for both household and commercial use, and easily meets export compliance requirements.

Compared to other plastic materials, PP (polypropylene) maintains high load-bearing capacity while being lighter overall, thus reducing transportation and storage costs.

Using a one-piece molding process, the box structure is robust, not easily cracked, and will not deform even after long-term use.

Using a one-piece molding process, the box structure is robust, not easily cracked, and will not deform even after long-term use.

Customization of size, wall thickness, color, and structure is supported. Long mold life makes it ideal for large-volume orders and long-term cooperation in the international market.

Product Introduction

ABS injection molded electronic device housings are among the most widely used, technologically mature, and consistently in high demand ABS materials in the injection molding industry.

These products are widely used in household appliances, electronic equipment, industrial controllers, smart terminals, and commercial equipment, and are common standardized injection molded structural parts in the international market.

Core Advantages of ABS Injection Molded Electronic Housings

ABS combines good rigidity and impact resistance, making it ideal for structural housings. It is not easily broken and offers high safety.

The material has a high surface finish, making it easy to spray, electroplat, and screen print, meeting the appearance and quality requirements of the international market.

ABS has low molding shrinkage and good dimensional stability, making it suitable for multi-part assembly and mass production.

Suitable for complex structural designs, it can mold snap-fit components, reinforcing ribs, and mounting posts in a single step, reducing secondary processing costs.

Supports customization of colors, structures, and surface treatments. The molds have a wide range of applications, making them ideal for long-term project collaborations in the injection molding industry.

Product Introduction

PC injection molded transparent protective cases are one of the core products made from PC material, with the widest application range and most stable international market demand in the injection molding industry.

These products combine high transparency, high strength, and impact resistance, and are widely used in industrial equipment, electronic and electrical equipment, security equipment, and commercial equipment, maintaining a long-term and stable demand in the international market.

Core Advantages of PC Injection Molded Transparent Protective Cases

PC has excellent light transmittance, providing a clear appearance, suitable for applications such as observation, display, and protection.

Its impact strength is far higher than ordinary plastics, making it less prone to breakage and safer than glass and acrylic.

Good molding stability, suitable for medium to large-sized housings, ensuring assembly accuracy and structural consistency.

Can be used for extended periods in high-temperature environments, suitable for electronic, electrical, and industrial applications. 5. Suitable for Export-Grade Custom Production

Supports transparent, semi-transparent, and color customization; adaptable to complex mold structures; suitable for OEM/ODM projects.

Product Introduction

PMMA injection molded transparent display covers are one of the most mature and recognized core acrylic materials in the injection molding industry.

These products are renowned for their high transparency and excellent surface finish, and are widely used in commercial displays, appliance panels, lighting equipment, instrument windows, and consumer electronics housing components, with stable demand in the international market.

Core Advantages of PMMA Injection Molded Transparent Display Components

PMMA has high light transmittance and good surface gloss, providing superior visual effects compared to most transparent plastics.

The injection-molded surface is smooth, easy to polish and surface-treat, making it ideal for display and decorative applications.

Low injection shrinkage and structural stability make it suitable for medium to large-sized transparent housings and panels.

Excellent UV resistance, suitable for long-term indoor and outdoor applications, and does not easily yellow.

Supports customization of color, thickness, structure, and surface treatment to meet the needs of OEM/ODM export projects.

Product Introduction

PA (Nylon) injection molded structural supports are one of the core products in the injection molding industry, with the widest application range, strongest engineering performance, and stable export demand.

These products are widely used in mechanical equipment, internal structures of home appliances, industrial parts, automotive and general industrial assembly systems, and are common high-strength injection molded structural components in the international market.

Core Advantages of PA Injection Molded Structural Parts

PA has excellent mechanical strength and fatigue resistance, making it an ideal material for load-bearing and stress-bearing components.

Nylon materials have excellent wear resistance, suitable for environments with long-term movement, friction, or repeated use.

High-precision molding processes can achieve integrated molding of reinforcing ribs, holes, and snap-fit components, thereby reducing assembly costs.

Suitable for industrial and household appliance internal environments, maintaining stable performance even in high-temperature or oily environments.

Supports glass fiber reinforced (PA+GF), color, and structure customization, making it an ideal choice for long-term OEM/ODM project cooperation.

Product Introduction

TPU/TPE injection molded protective shells and flexible functional components are among the most widely used and have the most stable export demand in the injection molding industry.

These products are widely used in electronic equipment protection, industrial equipment housings, household appliance and tool housings, pet supplies, and daily necessities, combining flexibility and structural stability, and are highly popular in the international market.

Core Advantages of TPU/TPE Injection Molded Products

This material has excellent resilience, suitable for product structures requiring a soft touch and cushioned protection.

It maintains stable performance under drop and compression conditions, effectively protecting the internal structure.

TPU/TPE has good wear resistance and environmental adaptability, suitable for both indoor and outdoor environments

Can be overmolded with rigid plastics such as ABS, PC, and PA, enhancing product added value and appearance.

Materials comply with RoHS, REACH, and other environmental requirements, suitable for international trade markets.

Product Introduction

PVC injection molded protective housings and functional structural components are among the most widely used and cost-effective product types in the PVC injection molding industry.

These products are widely used in daily necessities, home appliance parts, electrical protection components, industrial housings, and public facility accessories, enjoying long-term and stable market demand in the international market.

Core Advantages of PVC Injection Molded Products

The stable and reasonable price of PVC raw materials makes it an ideal choice for bulk export orders.

PVC itself is flame retardant, suitable for electrical and safety protection products.

Performance is stable in humid, acidic, and alkaline environments, suitable for long-term use.

By adjusting the formula, rigid structural components or flexible functional components can be produced.

Suitable for injection molding complex structures, ensuring dimensional stability and reliable appearance

Product Introduction

Injection molded rubber protective shells and functional structural components are among the most mature and widely exported rubber material product types in the injection molding industry.

These products are widely used in industrial equipment protection, appliance and tool housings, transportation and public facility components, pet supplies, and daily necessities, meeting international market requirements for reliability and safety due to their excellent elasticity and durability.

Core Advantages of Injection Molded Rubber Products

Effectively absorbs shock and vibration, suitable for protective and cushioning product structures.

Stable performance under long-term friction and outdoor environments, reducing replacement frequency.

Resistant to high and low temperatures and humid heat, suitable for various application scenarios.

High surface friction coefficient, improving safety and operational stability.

Hardness, elasticity, and media resistance can be adjusted to meet diverse customization needs.

Dongguan Chenfeng Plastic Mould Co., Ltd. is a professional precision injection molding manufacturer, committed to providing customers with one-stop plastic mold OEM/ODM solutions.

Proficient in high-precision injection molding of complex structures, ensuring superior performance and assembly quality.

Offering a variety of surface treatment processes, including in-mold patching/in-mold sampling, two-color injection molding, and spraying, to enhance the texture and functionality of products.

From design support and mold development to mass production delivery, providing flexible cooperation models, taking full responsibility throughout the process, and strictly protecting customers’ intellectual property rights.

Possessing a complete quality control system to ensure the reliability and consistency of raw materials and finished products.

We are committed to becoming your close partner in expanding your market, helping you succeed with our reliable manufacturing capabilities. Welcome to contact us to discuss how to transform your ideas into best-selling products.

Injection molding offers numerous benefits to business owners and manufacturers:

As a professional manufacturer of plastic injection molds, rubber molds, and custom injection molds, we offer:

From conception → 3D design → mold → finished product.

High-precision CNC machine tools, EDM machines, and injection molding machines.

Over 10 years of experience in mold design and manufacturing.

Every step undergoes rigorous inspection: molds, sample production, and mass production.

Rapid prototyping and efficient mold making.

We work with customers in the US, UK, Germany, Japan, and many other markets.

Factory-direct pricing, enabling long-term and stable partnerships.

Our team is ready to provide comprehensive support for your project from concept to mass production.

We design and manufacture high-precision custom injection molds tailored to your product requirements.

We produce high-quality plastic and rubber components with stable performance and strict quality control.

We provide flexible OEM and ODM services, supporting customization from design to finished products.

We deliver complete one-stop manufacturing solutions, integrating design, tooling, production, and assembly.

Our engineering team offers full project development support, from concept validation to technical optimization.